Our mission is to make e-waste recycling a secure and environmentally responsible process.

Our state-of-the-art recycling facilities carefully extract reusable materials in an environmentally friendly manner, helping to reduce both our and your business’s carbon footprint. We offer certified services for computer recycling, laptop recycling, CPU recycling, and other electronic waste disposal solutions.

Mobile Phone

Mobile phones which are not identified as suitable for refurbishment are sent to our Recycling Centre Section (RCS) for dismantling and sorting for component recycling or metal extraction. All processes align with our high standards of electronics recycling in Australia. Before any phone enters the recycling phase, our technicians ensure any sensitive data is erased through our certified data deletion services.

Monitors & Displays

We provide safe, compliant computer monitor recycling, including CRT and flat panel displays. CRT units contain recoverable lead and glass, which are processed through a cutter system that separates and collects materials. Each unit is tracked, and a detailed report ensures transparency. After cutting, components are heated, vacuum-treated, and all circuit boards and chips are recycled separately. Flat panel displays are dismantled, shredded, and processed through magnetic and eddy current separators to recover ferrous and non-ferrous metals. These are refined to achieve 99.9% purity. We support responsible PC monitor recycling and computer screen recycling, ensuring compliance and sustainability.

Battery

The battery recycling process begins by breaking the batteries; this is done to recover the lead. The battery head is removed, acid neutralised, and the unit processed in a hammer mill. Lead plates are extracted via a trammel, while plastic is separated through clarifiers and stored as furnace feed for recycling.

Once we’ve completed the furnace smelting and it’s been cleaned of molten oxides and sulphides, the metal is then treated for alloy specification to discard metals like copper, antimony, tin etc. They are then casted into lead ingots and can then be reused. Trust us for the best lithium battery disposal Perth and Darwin as this job is only done by our experts with years of hands on experience.

Printed Circuit Boards

Electronic Printed Circuit Boards contain many materials that are complex in nature, and they need a large amount of energy and other materials to make - vast quantities of metals like copper, nickel, and lead can also be found in them. Firstly, the components are all dismantled, pulverised and then shredded. The blank board and its components is the output from the initial processing stage; these blank boards mainly consist of smelted and electro-refined copper to create 99.9% pure copper bars. All separated components are then organised and classed as either heavy or light chips. All components are smelted so as to obtain pure metals, and all plastic components are separated by density-based separation.This process helps with computer waste recycling and keeps valuable resources out of landfills.

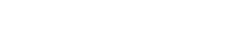

General I.T

General I.T. goods are things like desktops, laptops, servers, printers, scanners, copiers etc. Once these goods have been delivered to our recycling plant, they are assessed for computer disposal and recycling to determine whether those goods need to be recycled or refurbished, A key step in our IT asset lifecycle management workflow. Recycled goods go to the Recycling Centre, refurbished ones to Refurbishing Operations, while remaining components are shredded and processed through magnetic separation.

Apple computer recycling, recycling laptop computers, and secure ewaste disposal are all part of our comprehensive service. Whether it’s a single old computer or an entire fleet of outdated IT assets, we provide reliable e-waste recycling services in accordance with Australian e-waste laws and environmental standards. Our end-to-end services cover everything from recycling old computers to complex CPU recycling and computer screen recycling. We also offer test and tag services for electronic equipment before disposal or refurbishment to ensure compliance and safety.

Mobile Phone

Mobile phones which are not identified as suitable for refurbishment are sent to our Recycling Centre Section (RCS) for dismantling and sorting for component recycling or metal extraction. All processes align with our high standards of electronics recycling in Australia. Before any phone enters the recycling phase, our technicians ensure any sensitive data is erased through our certified data deletion services.

Monitors & Displays

We provide safe, compliant computer monitor recycling, including CRT and flat panel displays. CRT units contain recoverable lead and glass, which are processed through a cutter system that separates and collects materials. Each unit is tracked, and a detailed report ensures transparency. After cutting, components are heated, vacuum-treated, and all circuit boards and chips are recycled separately. Flat panel displays are dismantled, shredded, and processed through magnetic and eddy current separators to recover ferrous and non-ferrous metals. These are refined to achieve 99.9% purity. We support responsible PC monitor recycling and computer screen recycling, ensuring compliance and sustainability.

Battery

The battery recycling process begins by breaking the batteries; this is done to recover the lead. The battery head is removed, acid neutralised, and the unit processed in a hammer mill. Lead plates are extracted via a trammel, while plastic is separated through clarifiers and stored as furnace feed for recycling.

Once we’ve completed the furnace smelting and it’s been cleaned of molten oxides and sulphides, the metal is then treated for alloy specification to discard metals like copper, antimony, tin etc. They are then casted into lead ingots and can then be reused. Trust us for the best lithium battery disposal Perth and Darwin as this job is only done by our experts with years of hands on experience.

Printed Circuit Boards

Electronic Printed Circuit Boards contain many materials that are complex in nature, and they need a large amount of energy and other materials to make - vast quantities of metals like copper, nickel, and lead can also be found in them. Firstly, the components are all dismantled, pulverised and then shredded. The blank board and its components is the output from the initial processing stage; these blank boards mainly consist of smelted and electro-refined copper to create 99.9% pure copper bars. All separated components are then organised and classed as either heavy or light chips. All components are smelted so as to obtain pure metals, and all plastic components are separated by density-based separation.This process helps with computer waste recycling and keeps valuable resources out of landfills.

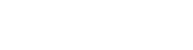

General I.T

General I.T. goods are things like desktops, laptops, servers, printers, scanners, copiers etc. Once these goods have been delivered to our recycling plant, they are assessed for computer disposal and recycling to determine whether those goods need to be recycled or refurbished, A key step in our IT asset lifecycle management workflow. Recycled goods go to the Recycling Centre, refurbished ones to Refurbishing Operations, while remaining components are shredded and processed through magnetic separation.

Apple computer recycling, recycling laptop computers, and secure ewaste disposal are all part of our comprehensive service. Whether it’s a single old computer or an entire fleet of outdated IT assets, we provide reliable e-waste recycling services in accordance with Australian e-waste laws and environmental standards. Our end-to-end services cover everything from recycling old computers to complex CPU recycling and computer screen recycling. We also offer test and tag services for electronic equipment before disposal or refurbishment to ensure compliance and safety.

- Desktop Computer

- Tablet Computer

- Monitor (LCD/LED)

- Data Storage Devices

- Television (LCD/LED)

- Network appliances

- Whiteboard (Electronic/Interactive)

- Scanner

- Multi Functional Device

- Plotters/Large Format Printers

- All In One Computer

- Thin Client

- Server

- Mobile Telephone

- Television (CRT)

- Camera (Digital/Still/Digital Video)

- Consumables (Toner, inkjet, etc.)

- Printer (Inkjet/Laser)

- Other ICT goods

- Computer Accessories

(Keyboards, mice, docking etc.) - Netbook Computer

- Notebook Computer

- Telephone

- Smartphone/PDA

- UPS (Only)

- Projector

(Data/Multimedia) - Large Format Display

(LCD/LED) - Facsimile Machine

- Photocopiers

- VCR/DVD/CD/Disk/Tape Drives Radios/Players

- Battery backups, ICT batteries, laptop batteries

- Monitor (CRT)